Types and methods of metal processing

Metal processing in Lviv is our main specialization. Therefore, it is necessary to reveal this topic in more detail. What is metal processing? This is a process that consists in influencing metal or metal alloys with the help of manual labor or special equipment, in order to achieve certain forms, characteristics, dimensions, etc.

⠀

What are the main metal processing methods? There are four of them:

- Mechanical processing (cutting).

- Processing of metals under pressure.

- Welding.

- Casting.

All of them can be used both individually and in a complex and various combinations with each other. Let's look at each of them further.

⠀

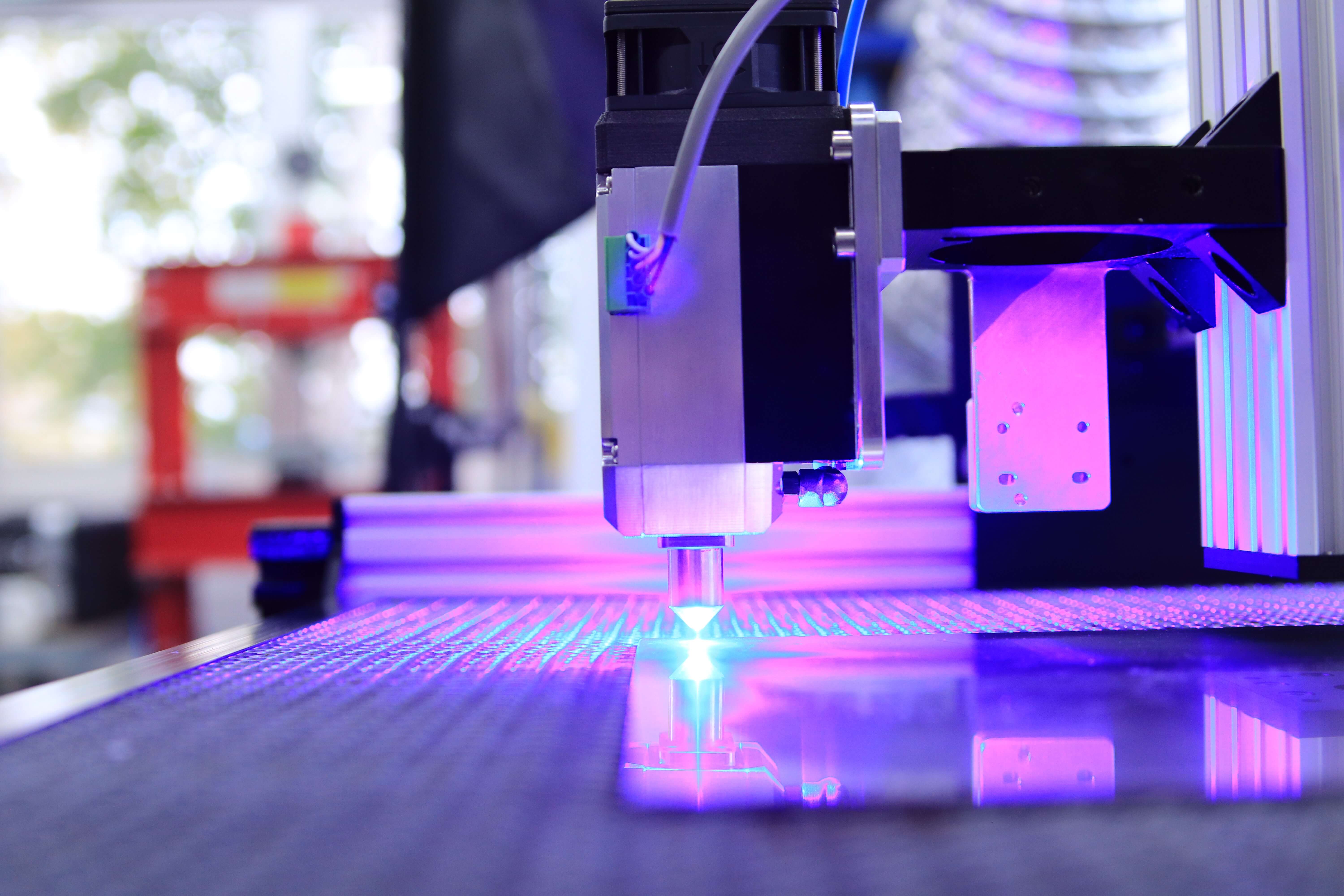

Mechanical (milling) processing or cutting is a technology that is a mechanical effect on materials with the help of tools that, cutting, remove excess. As a result of this process, the metal acquires the required shape.

Mechanical processing has several varieties:

- Turning processing.

- Thread cutting.

- Influence of abrasive materials.

- Processing with a file.

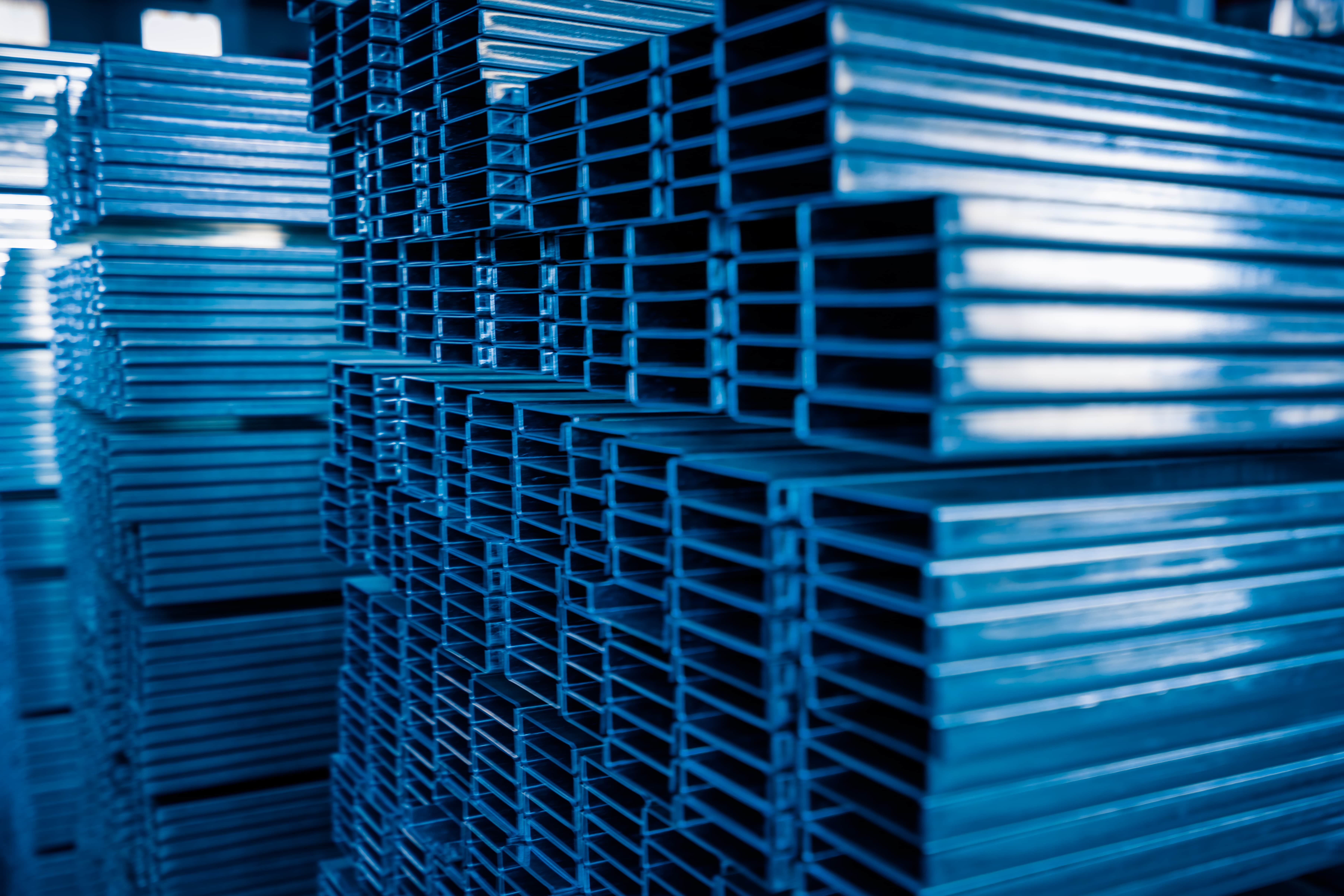

Processing of metals under pressure involves processes aimed at changing the shape and configuration of the metal workpiece while preserving its integrity. It is divided into several types:

- Pressing, the basis of which is the extrusion of metal from the cavity of the matrix with the help of a press.

- Rolling is a technological process during which the rolls of the rolling mill, which rotate, compress the initial workpiece.

- Drawing is the process of drawing metal blanks through a narrowing hole in a tool called a draw.

- Forging is a high-temperature operation that involves preliminary heating of the workpiece to a certain forging temperature depending on the metal grade.

- Three-dimensional stamping is a type of impact on a metal blank with a stamp, as a result of which the semi-finished product acquires a given shape.

- Sheet stamping is the effect of pressure on metal, as a result of which the raw material is deformed and transformed into thin-walled blanks and parts for enterprises in the machine, shipbuilding, and automobile industries.

Metal welding is a process of combining two or more metal elements under the influence of temperature. It looks like this: the edges of metal products are heated, and under the influence of temperatures they will begin to melt, join and harden. As a result, a strong seam is formed. There are several types of welding:

- electrical;

- gaseous;

- cold;

- ration.

The casting method involves preliminary melting of the metal, after which it is poured into forms in which it solidifies. Products made by casting are called castings.