Types and marking of steel

Although steel is compared to iron, it is actually an alloy in which, in addition to iron itself, there are many other metals and substances in the form of impurities. As a result, steel has different types and markings, which we will talk about later.

⠀

So, by what features do we classify and mark steel? There are several such signs:

- by the degree of doping;

- by steel quality;

- by appointment;

- according to the method of deoxidation.

According to the degree of alloying (the content of alloying elements), steel is divided into:

- Low-alloyed (the share of alloying elements in the composition is no more than 2.5%).

- Medium-alloyed with a share of alloying elements from 2.5 to 10%).

- Highly alloyed (more than 10% - alloying additives).

Such elements make steel stronger, and resistant to corrosion, magnetic field, etc.

⠀

According to the quality of steel, we distinguish:

- Quality steel;

- High-quality steel;

- Especially high-quality steel.

Quality characteristics of steel include hardness, strength, corrosion resistance, durability, and heat resistance. Quality also means the minimum percentage of phosphorus impurities (maximum 0.02%) and sulfur (maximum 0.015% for the higher index), which negatively affect the strength and heat resistance of steel.

⠀

By purpose (functions), steel is divided into:

- Structural (0.07-0.8% carbon);

- Instrumental (0.7-1.3% carbon);

- Precision (over 1.3% carbon)

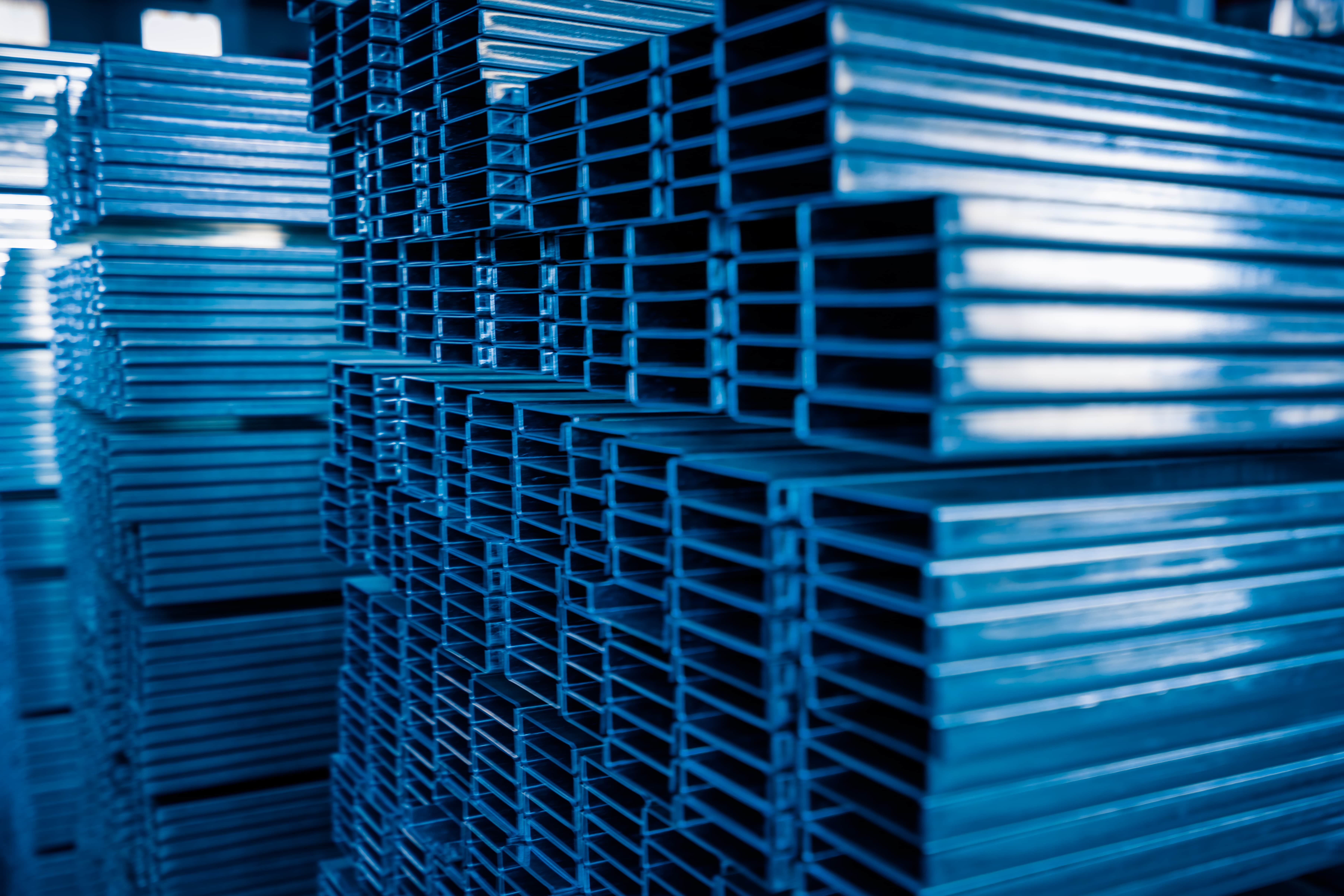

Structural steel can carry loads as support. It is often used as part of the frame of buildings.

⠀

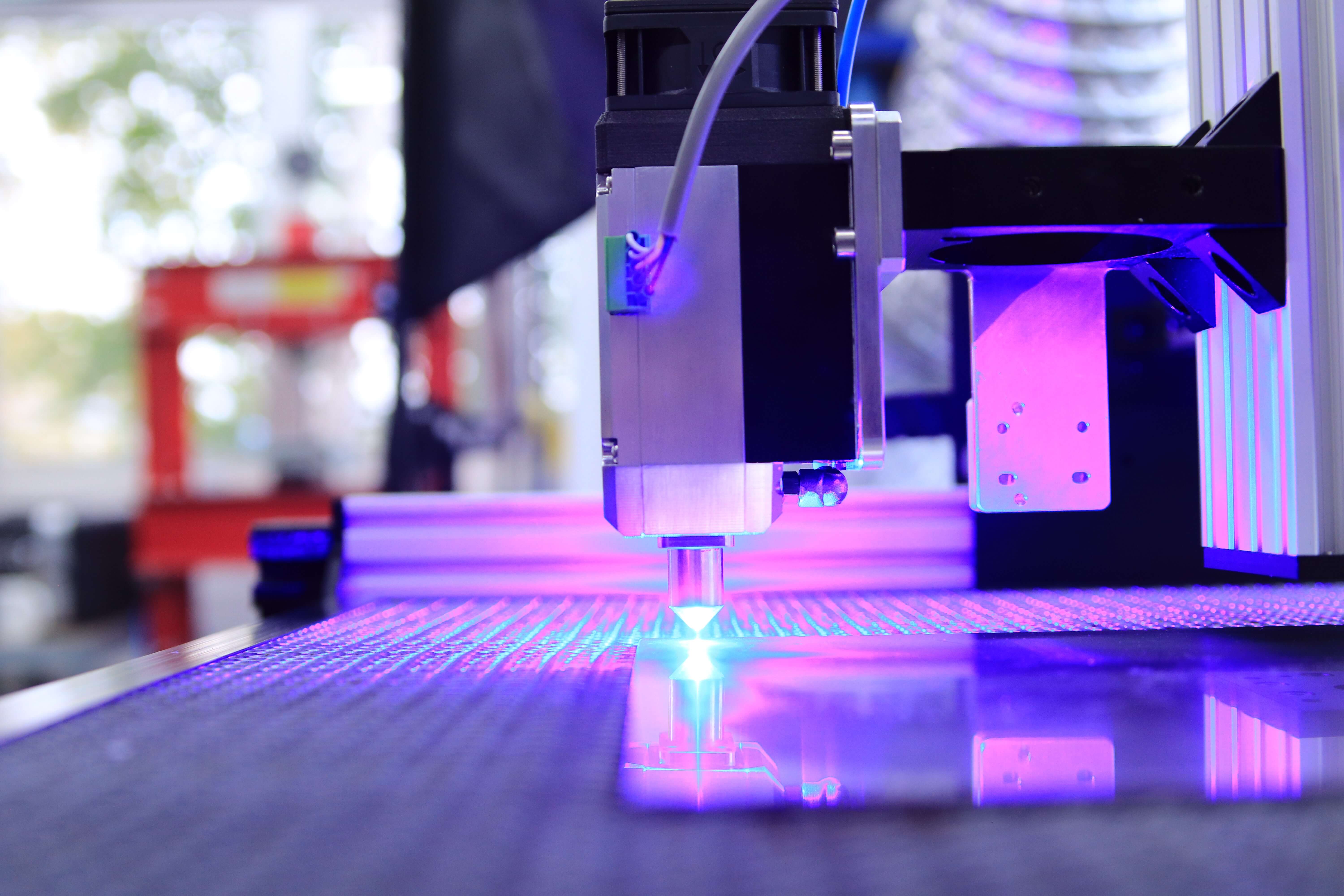

Tool steel has increased hardness and strength, it can be used to make tools for processing wood, metal, stone, etc.

⠀

Precision steel has special properties: heat resistance, wear resistance, stainless steel, and steel with special magnetic or thermal properties. This is a steel of increased hardness, used for the production of high-precision tools, including surgical

⠀

According to the method of deoxidation, steel is:

- killed steel deoxidation;

- semi-killed deoxidation steel;

- rimmed deoxidation steel;

- capped deoxidation steel.

⠀

What are the markings of steel?

⠀

Marking can include letters and numbers. Numbers usually indicate the content of alloying additives or specific elements in the composition of alloy steel. You can also specify the quality category of the material. The letters denote the abbreviations of the steel brand, purpose, quality, and other indicators

⠀

What are the grades of steel and their generally accepted designations? Let's figure it out further.

⠀

The first digit of the steel grade indicates the carbon content in hundredths of a percent. One number before the first letter of the marking indicates the carbon content in tenths of a percent. If the carbon content exceeds 1%, numbers are not placed before the letters.

⠀

The marking is followed by a letter indicating the presence of the appropriate alloying element in the steel. The number after the letter indicates the average content of the alloying element, and if the content of the element is less than 1.0-1.5%, then the number is not indicated. In some cases, the content of alloying elements can be specified.

⠀

For example, steel 32X06L contains an average of 0.32% carbon and about 0.6% chromium. The letter "L" at the end indicates that the steel is a foundry.

⠀

The letter "A" is added at the end of the marking to indicate that this is a high-quality alloy steel. High-quality steel contains less sulfur and phosphorus than high-quality steel.

⠀

Alloyed tool steels are marked according to the same system as structural steels, with the difference that the first number indicates the carbon content in tenths of a percent, not in hundredths. For example, 9KHVG steel contains 0.85-0.95%, 0.5-0.8% Cr, 0.5-0.8% W, and 0.9-1.2% Mn.

⠀

Some special-purpose steels are separated into separate groups and have special markings. Each group is given its own letter and placed in front of it:

- Ж – chrome-plated stainless steel.

- I - chrome-nickel stainless steel;

- P - high-speed steel;

- Ш - ball bearing steel;

- E - electrical steel.

For example, steel ShKHN15, Zh1, P18.