Blog

Our expertise and experience will be useful both to beginners - specialists in metalworking and to our customers. Every week we publish relevant materials about novelties in the field of metalworking, technologies, news, and achievements of our company on the market. In the blog, Lezometal company experts provide only practically proven information in an accessible and understandable language. It will be interesting!

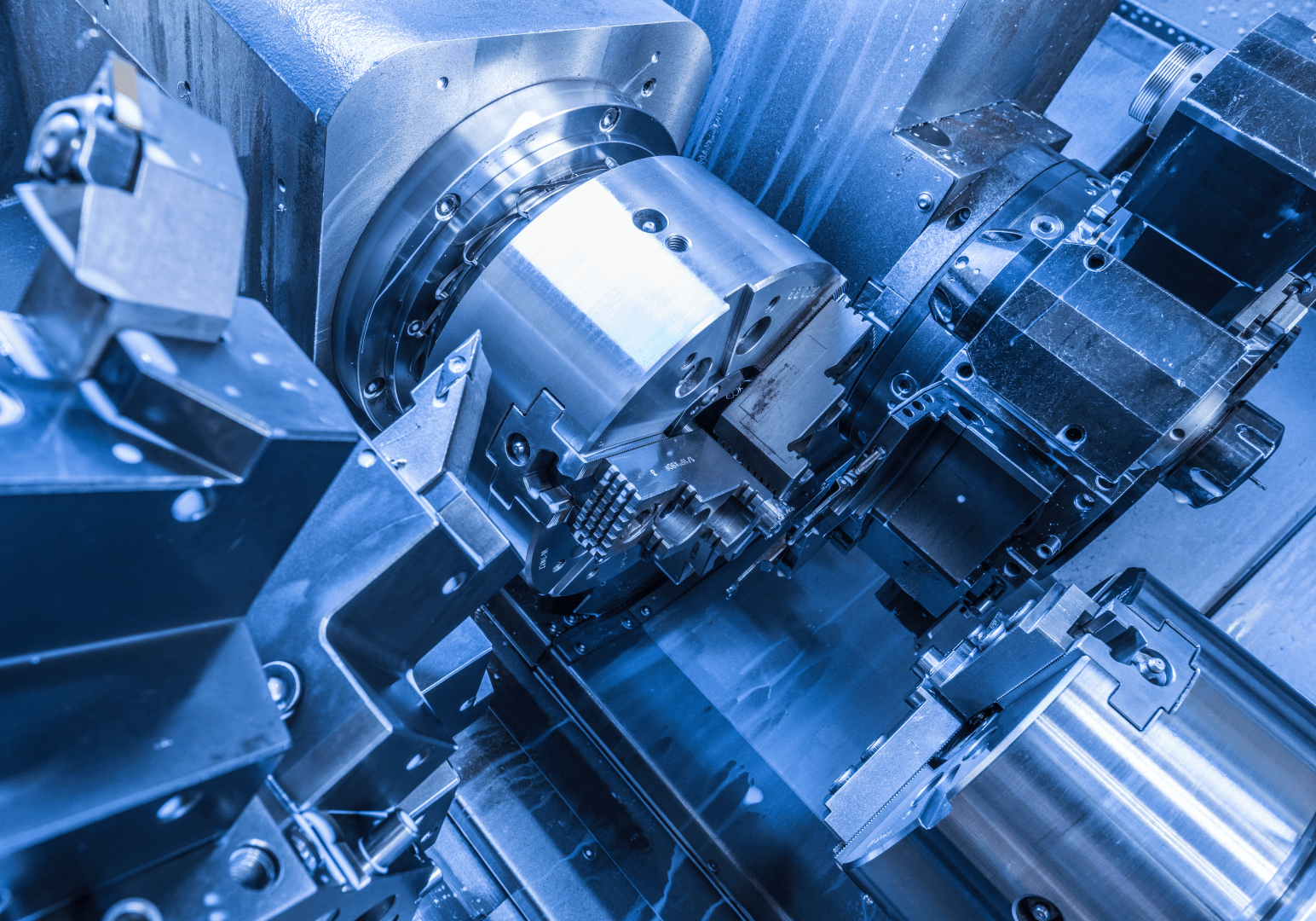

Pluses and minuses of CNC metalworking

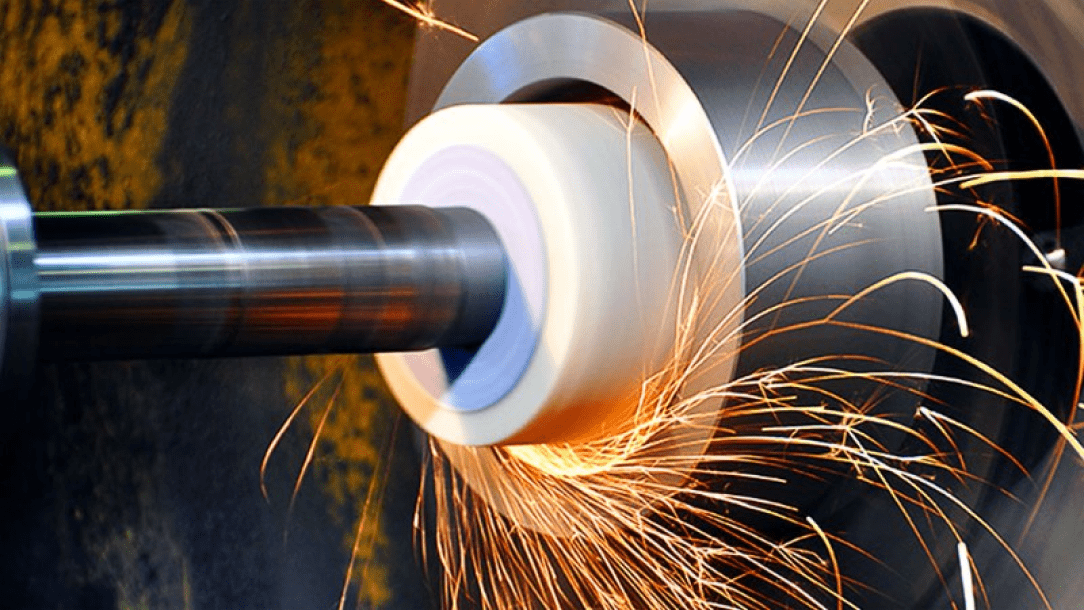

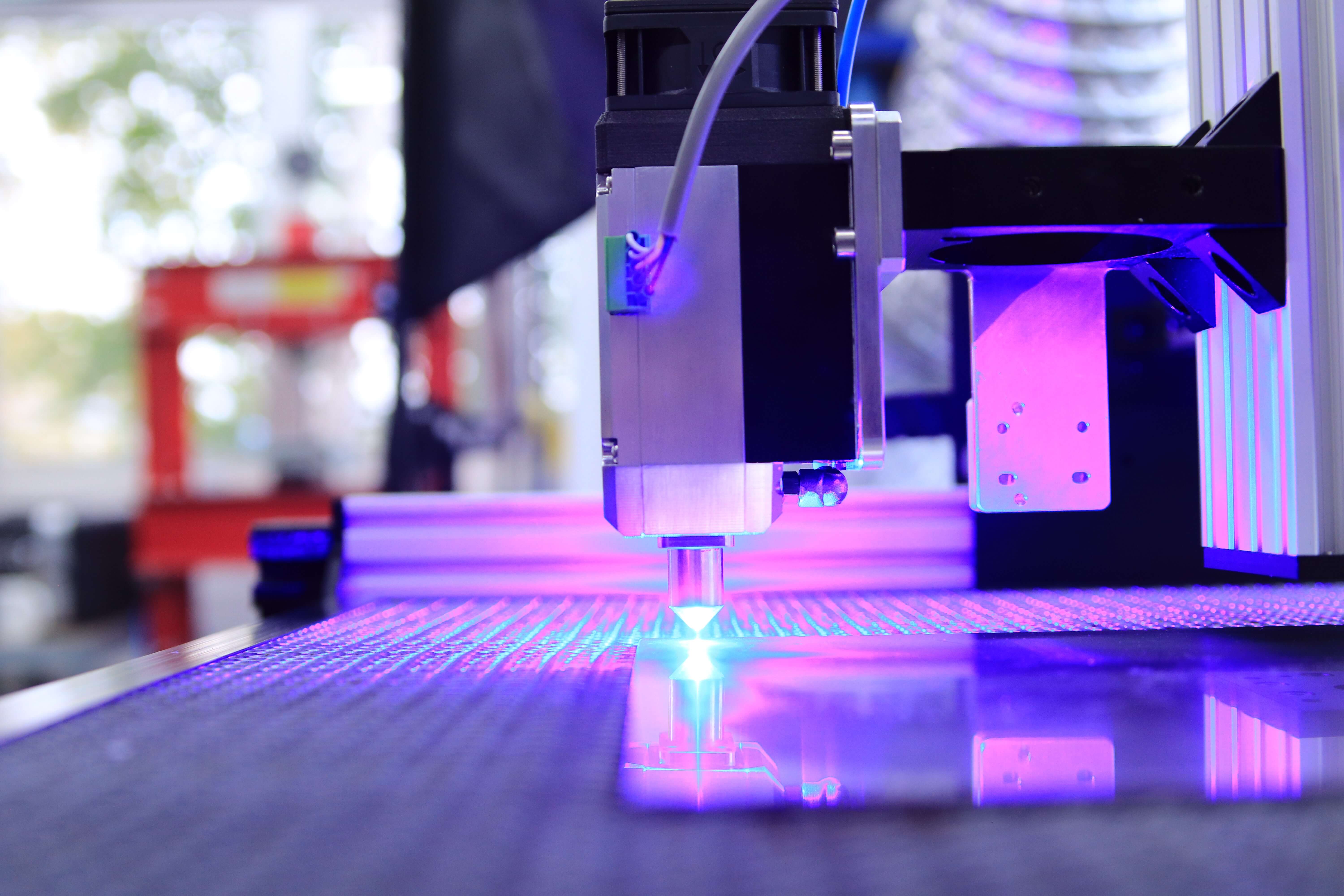

Metalworking on CNC machines is one of the most modern methods of processing alloys. CNC machines allow specialists to produce a larger number of parts than manually at the same time. In addition, the accuracy of this method of processing metals and alloys is 1:1000, which practically eliminates the human factor.

⠀

What are the advantages of metalworking on CNC machines?

⠀

The advantages of metal processing on CNC machines include:

- High processing accuracy is guaranteed. We manufacture any number of parts in a short period of time, the accuracy of which is 1 to 1000.

- Exclusion of the influence of the human factor. The operator of CNC machines does not affect the quality of the production of parts, but only ensures the loading and unloading of parts from the machine, and manages its operation.

- Performing several operations on one machine. To save time and speed up the execution of the order, it is possible to perform several operations on the same machine. The operator does not need to load and unload the workpieces each time for a new processing step.